At Rocks by Rail we have the most comprehensive collection of standard gauge quarry railway rolling stock in the UK. Scroll down to browse our exhibits or click on a link below to go to your area of interest:

BRAKE VANS – brake assistance for loose coupled wagons on mainline trains.

CALCINE WAGONS – used to move ironstone for calcining.

CHALK and CLAY TIPPLER WAGONS – for transporting raw materials from the quarry to the cement works.

DUMPCAR WAGONS – typically used to move ironstone, sand and overburden during quarrying.

HEAVY PLANT WAGONS – for transporting machinery.

HOPPER WAGONS – carry iron ore from the quarry face to the steel works.

ORE TIPPLER WAGONS – carry iron ore from the quarry face to the steel works.

PLATE LAYERS – for maintaining the rail tracks.

ROCKS BY RAIL MUSEUM SERVICE WAGONS – wagons for the maintenance and running of the Museum.

WOODEN WAGONS – early wagons used in ironstone quarries.

RESERVE COLLECTION – wagons not in service.

HOW A TIPPLER WORKS

An image with a blue border indicates exhibit is no longer at the museum. We have no information regarding the current whereabouts or status but you could try UK & Ireland Heritage Railways site.

BRAKE VANS

When trainloads of minerals were worked over the mainline railways, the long loose coupled trains were supervised by the Guard who rode in his own vehicle at the back of the train. This contained a heavy duty brake to assist stopping the train but also carried the lamps and paperwork record for the train. Visitors will also see the working environment provided for the guard.

The Museum currently has four Brake Vans to operate with our trains on the steep branch line but also to provide authentic visitor rides.

LMS 20-ton built in 1926.

The Furness Railway Trust

built at Ashford for the Army.

Shark.

CALCINE WAGONS

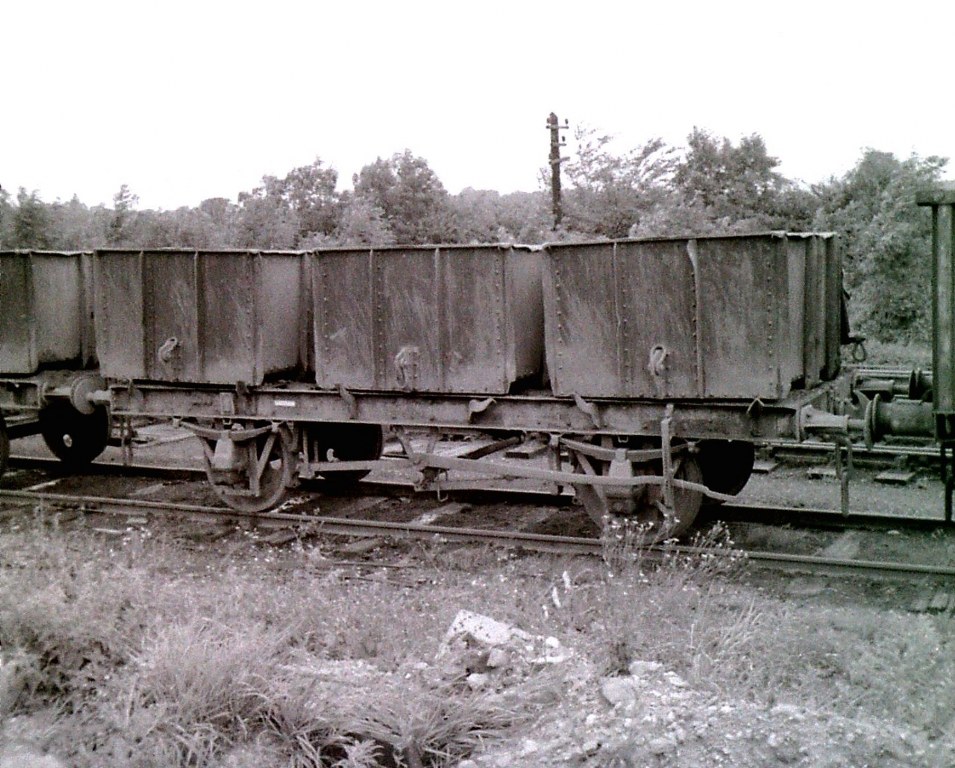

In certain quarries ore was mixed with coal slack and a process of “Calcining” which burnt the raw ore was carried out to drive off volatile material and reduce weight. This was particularly relevant when the ore had to be taken a long way and Burley Quarry, for instance, employed the method for its ore, which had to be taken to the Dorman Long steelworks in the North East. In many cases when the ore wasn’t burnt on the quarry floor, internal wagons were used to transport the ore from the quarry to the “cally banks”. These were often in the style of the older side tipping “ship canal” designs originating in the earliest days of railways. Later these were replaced with four-wheel steel skip wagons and we were able to preserve two rare examples built by G R Turner of Langley Mill in 1942, each having three transverse skips, these being lifted by a dedicated crane at the clamps. They were often used for delivery of coal to the calcining operation where layers of coal slack were mixed with the raw ore to part smelt it before the onward journey to the steelworks.

Stewart & Lloyds (Minerals) Ltd

Stewart & Lloyds (Minerals) Ltd

CHALK and CLAY TIPPLER WAGONS

The quarry railways at Ketton, Rutland and Barrington in Cambridgeshire used specific internal user tippler wagons to transport the raw materials for the cement making process from the on-site quarries to the production plant.

We were donated representative wagons from both railway systems. These now form two rakes for demonstration purposes with Thomas Hill Mr. D on the four Barrington wagons and Fowler Ketton No.1 with 3 Ketton tipplers on the Cements Quarry Open Days.

Note reverse hand brake levers.

Note reverse hand brake levers.

Note reverse hand brake levers.

DUMPCAR WAGONS

Also known as side-tipping wagons, these 15-ton buckeye coupling fitted wagons were inspired by American practice and were pioneered in Britain and the ironstone ore fields by the Oxfordshire Ironstone Company. They were built from 1920 by Gloucester C&W Co., Metro-Cammell and Birmingham Railway Carriage & Wagon to work from quarry face to the crushing plant at Wroxton. They were later used at other quarries particularly Corby for moving overburden and sand excavated during quarrying.

Built by Metro-Cammell in 1940.

Built by Metro-Cammell in 1940 (fitted with converter draw gear).

Built by Metro-Cammell in 1940 (fitted with converter draw gear)).

Built by Metro-Cammell in 1940.

HOPPER WAGONS

The introduction of steel hopper wagons in the 1930’s heralded attempts to improve the load carrying capacity for ore traffic with purpose built wagons suitable for loading at the quarry face and easy discharge at the steel works. Unlike “ore tippler wagons“, these were less efficient for unloading with a bottom door for discharge. When the railways were nationalised, many wagons were pooled to BR.

It was not uncommon for coal hoppers to find their way into ore traffic often with dire consequences for the lifespan of the wagons concerned.

Metro-Cammell.

Metro-Cammell.

Metro-Cammell.

Charles Roberts for Appleby-Frodingham Steel Company. Nationalised and pooled but retained for ore traffic particularly to Scunthorpe from United Steel quarries at Cottesmore, Exton Park and Colsterworth.

ROCKS by RAIL MUSEUM SERVICE WAGONS

We have a number of wagons that are used to support the running and maintenance of the Museum.

ORE TIPPLER WAGONS

After the railways were nationalised under British Railways a “Modernisation Plan” was introduced. This started a rapid process to replace less efficient wagons (see “hopper wagons“) in the home iron ore industry with simple, robust low tare weight “tipplers” capable of working from the quarry face to steelworks where the wagons were physically tipped over to discharge their contents. In all 9,590 wagons were built between 1951 and 1960 and very quickly becoming the ubiquitous wagon in the East Midlands ore fields. Our operational rakes represent the last phase of railway wagon operation from the mid-1950’s until the quarry closures of the 1970’s. Although similar, keen students will spot minor build differences between the wagons.

Lot No. 2730.

Lot No. 2730.

Lot No. 2730.

Lot No. 2844.

Lot No. 3091.

Lot No. 3324.

Lot No. 3363.

PLATELAYERS

Maintaining the permanent way requires a range of vehicles.

Ex Corby quarries.

6-plank mineral wagon.

RESERVE COLLECTION

Vehicles not in service.

HOW A TIPPLER WORKS

We have three types of tippler wagon at Rocks by Rail, calcining wagons, chalk and clay tipplers and ore tipplers.

Here an ore tippler wagon is being unloaded by being “tipped” sideways in a “tippler” machine as used at steelworks.

Here a three skip wagon is being unloaded prior to calcining. A Ruston Bucyrus RB55 machine is being used to tip the skip.

A three skip wagon seen here at Cranford.